One of the many interesting parts of this job is the detective work involved when a part isn’t welding properly. Roughly six months ago I was tasked with my first major metallurgical engineering project, which showed that the metal in your parts may have some hidden surprises.

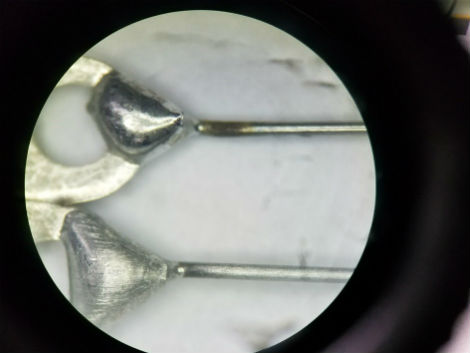

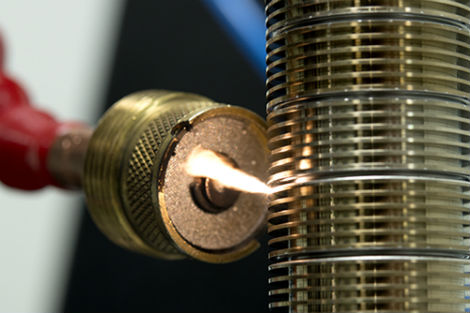

Soldering: not all flux is created equal

| This image shows a part with corrosion (top) and without (bottom). |

A recent issue with a soldering process for a customer has been the focus of our attention here at Joining Technologies for quite some time. Since it turned out to be a good learning experience, we thought it was worth sharing to explain issues that intermittently arise when soldering these types of assemblies.

Joint design for welding: the pros and cons of groove joints

After you’ve selected the right material for your welding project, the next important consideration is joint design. We’ll be taking a look at the different types of joints and briefly discussing the pros and cons of each, especially in relation to laser and electron beam (EB) welding. Let’s start with one of the strongest joints, the groove joint, and what makes it so "groovy":

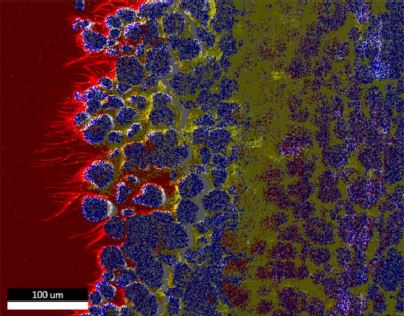

Weld contamination part 2 – aluminum oxide

| Aluminum oxide contamination is no big deal for that rusty yard art project, but can wreak havoc on critical applications like an axle shaft. (Spider by John Lucas, Jr.) |

I’ve talked about weld contaminants in a previous post, but a recent conversation convinced me that it was a topic that warranted revisiting.

Aluminum oxide (AlO), in particular, is a nasty contaminant that is oft overlooked.

Material selection for laser and EB welding - do's and don'ts

One of the most important factors in a successful laser or electron beam (EB) welding project is choosing the right materials up front. The right material can make the difference between a project that runs smoothly and gets delivered on time, and a project that takes longer, costs more, and causes a lot of aggravation. While we could probably write a book on this topic, here are a few do’s and don’ts to get started.

Heat treating, before or after welding (or both)

I’ve blathered about heat, post-weld heat treatment, heat sinking, and blown a lot of hot air in general. Mostly, the discussion has focused on weld characteristics and weldability. This blog will take a slightly different angle.

Heat treating can be used for a variety of reasons: strengthening, annealing, stress relieving, and wear resistance to name a few. But, when is the best time to heat treat your welded part?

Laser welding aluminum – stay light by welding with light

Warning: This is a blog, not a how-to guide. I won’t be giving away any secrets today. If you want those, it’ll cost you $$$!

This is a hot topic. Aluminum is a popular material due to its light weight, ease of machining, relatively low cost, and good wear and corrosion characteristics. It is commonly GTAW and MIG welded – think bicycle frames, hand rails, and truck tool boxes.

In Memory of Paul Lombardini

Folks, today I would like to shift gears from technical discussion and dedicate this blog to an exceptional individual.

Paul Lombardini, our Quality Control Manager, passed away on Tuesday, September 12, very unexpectedly. This man touched the lives of everyone he came in contact with. Writing this is surprisingly hard from an emotional standpoint, and exceptionally easy from a content standpoint.

Filler wire selection for welding

Choices, choices. The designer literally has all of them at some point. As the design progresses, they dwindle along with flexibility.

When designing a part for welding, there are times where it becomes necessary to incorporate filler material into the assembly. This can be to accommodate manufacturing tolerances, to reduce stress, or to join materials that may not readily weld without an intermediary.

These have to be considered when selecting an appropriate filler.

Five steps to planning your career growth

Guest blogger Sue Salvemini is the founder and president of Focal Pointe, Inc., which provides executive coaching, leadership development and business consulting services.

Climbing the corporate ladder often seems narrow and difficult to navigate. With limited senior level positions and multiple talent striving for the same job, the journey can be overwhelming and often discouraging.

As an individual, you enjoy your work, you like your colleagues, and your company is a great fit. Other than feeling stalled in career advancement, you are happy! So how do you advance and achieve your goals without feeling that your only option is to change jobs or companies? Are there opportunities right in front of you that you may be missing? Are you leading yourself intentionally with a focused direction?